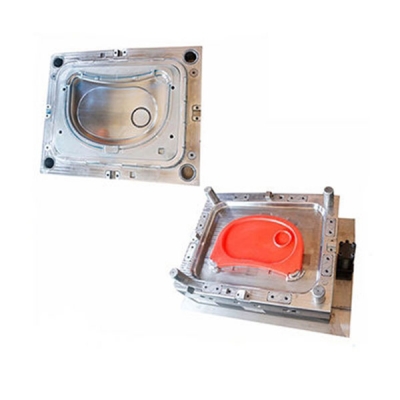

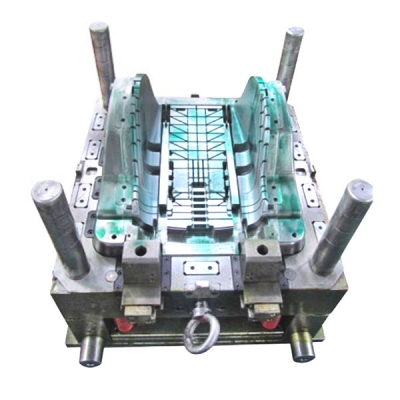

Ice Pop Groovy Plastic injection Mold

Place of Origin: China

Brand Name: OEM

Certification: ISO9001, ISO14001, IATF16949

Model Number: Ice Pop/Groovy Mould

Payment & Shipping Terms:

Minimum Order Quantity: 1 Set

Price: Discussion

Packaging Details: Artificial Wooden box

Delivery Time: 4-5 weeks after mould 3D approved

Payment Terms: T/T

Capacity: 45 sets per month