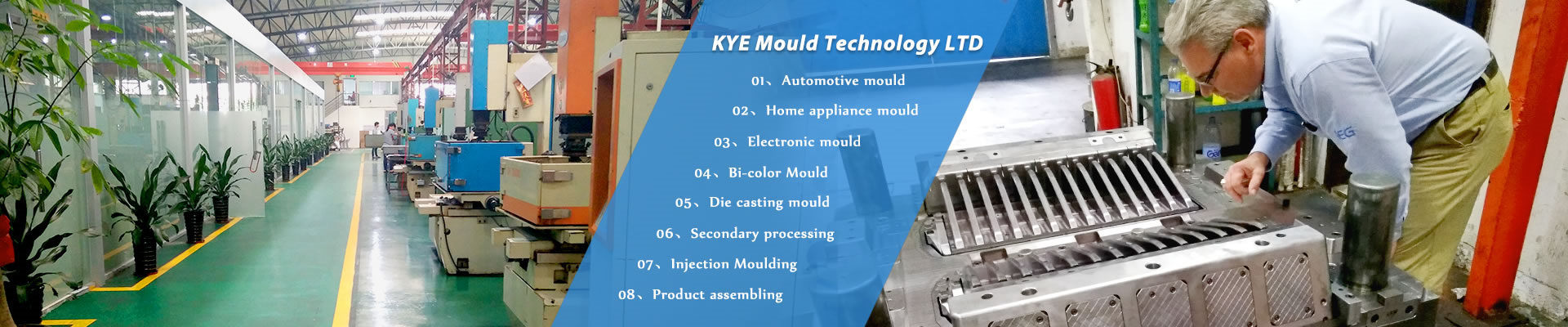

KYE Mould Technology Limited is a large scaled Chinese injection tool manufacturer with full experience on creating durable, high-quality molds and products. Our excellent engineered and experienced technical support to take your idea to be reality under one roof from mold design, prototype-making, Mold-flow analysis, molding to plastic part and die-casting parts producing. Industrial product accessories injection molding is one range of our main business.

Tee-pipe tubes are commonly used in plumbing, irrigation, and fluid distribution systems to create a T-junction where one pipe branches off from another. KYE is with the full experiece on Tee-pipe tube injection mold and molding that meet the required specifications and maintain the desired level of structural integrity and leak-free connections.

Precision-engineered: KYE Tee-pipe tube injection mold precision-engineered by KYE‘s expert team with state-of-the-art technology. KYE offer high-tech machining process (CNC, EDM or other techniques) to support the Tee-pipe‘s shape, size, and features necessary for proper fluid flow and connection.

The Tee-pipe tubes made by KYE mould is with high precision dimensions and smooth features. Our Tee-pipe tube injection molds are with first-level quality and meet DME/HASCO standard.

Prototyping: For ensure that the design adheres to safety guidelines for related product industry. KYE provide 3D printed prototype if neccessary.

Strict QC system: Quality Assurance is the key to success for KYE Moulds, high-quality/defect free products is the reason. Our quality control lab is equipped with optical Coordinate-Measuring achine(CMM), projector, Vickers/Rockwell hardness tester, salt spray tester,etc. Furthermore we have strict quality control process and related examination and testing stardards.

Trial running: While finish the mold assembly, KYE will arrange trial running and provide T1, T2 or T3 samples till meeting your satisfaction.

Trimming and Finishing: KYE experienced worker will trim off any excess material (flash) or imperfections after ejection, undergo additional finishing processes for Tee-pipe tubes, so that it can achieve the desired surface texture and appearance.

Mass Production: Mass Production and Assembly also can be done under our one roof if our customers place product order to us directly.

T-branch pipes are essential components in various piping systems. KYE precision molding process ensures the Tee-pipe tube molds are manufactured with high-quality and durability, it‘s meeting industry standards and fulfilling customer requirements for reliable and durable pipe components.

|

1.Mould standard |

DME |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

S50C |

|

4.A/B plate steel |

P20 |

|

5.Core/Caviry steel |

1.2083 |

|

6.Runner type |

Cold runner |

|

7.Gate type |

Sub gate |

|

8.Cycle time |

65s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

6 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

0.5 million shots |