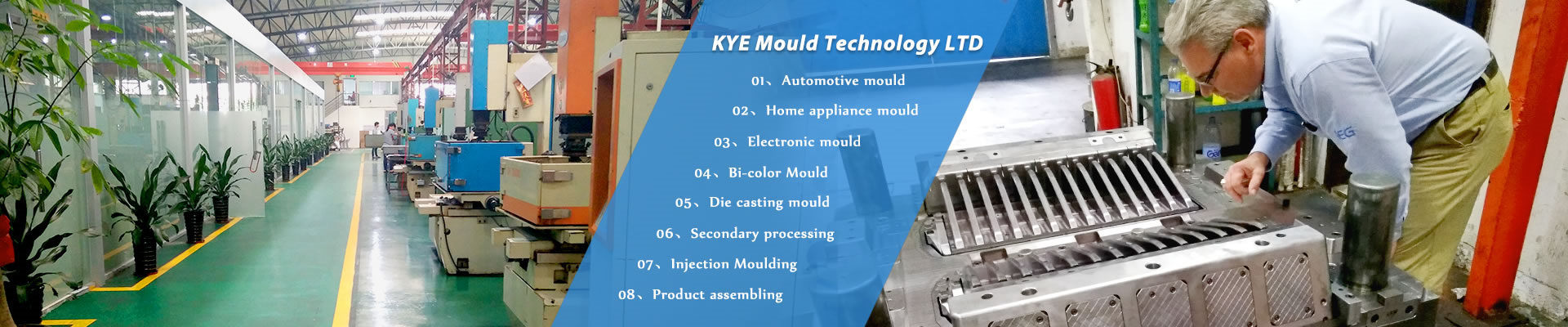

KYE Mould Technology Limited is a good quality Chinese injection tool manufacturer with full experience on injection molding more than 10 years. Babycare injetion mold is one range of our main business, Customized molding for Baby Chair Dinner Plate Tray Mould with DME/HASCO standard ,offering competitive price and one-stop service from mould design to mass production manufacturing.

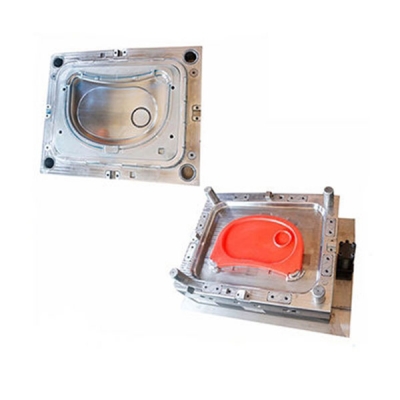

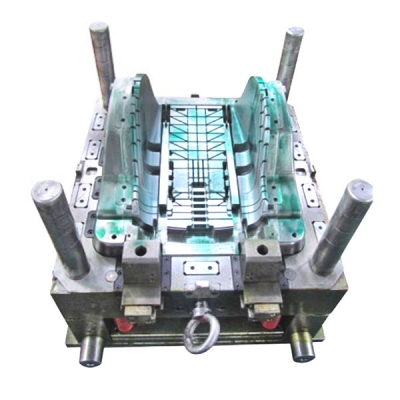

KYE plastic step seat injection mold , precision-engineered by KYE‘s expert team with state-of-the-art technology, safty material and safty design specially.

KYE engineers consider warnly the factors like safety, ergonomics, and ease of cleaning for all molds for babycare product during the design phase. Base on combine with the requirement from customers about dimensions, shape, and any additional features of the plastic step seat injection mold.

With our injection molding process, we can bring your designs to your product with precision and efficiency. It‘s like giving your ideas the power of a jet engine, propelling them forward at lightning speed. Our team of skilled technicians and state-of-the-art equipment work together seamlessly to ensure every detail is flawlessly executed.

While finish the mold assembly, KYE will arrange trial runner and provide T1, T2 or T3 samples till meeting your satisfaction.

Mass Production and assembly also can be done under our one roof if our customers place product order to us directly.

Quality Control: KYE QC team are strict inspection on the plastic step seat parts to ensure they meet the required standards. This include inspections for dimensional accuracy, strength, and safety.

If you are looking to manufacture plastic step seats , KYE will be your best solution since we are the experienced, competent and solution-oriented manufacturing company that specializes in mold design and injection molding. We will reaponsable to guide you through the process and produce the plastic step seats according to your specifications.

|

1.Mould standard |

DME |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

1.1730 |

|

4.A/B plate steel |

2312 |

|

5.Core/Caviry steel |

1.2344 |

|

6.Runner type |

Cold runner |

|

7.Gate type |

Sub-gate |

|

8.Cycle time |

32s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

4 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

1 million shots |