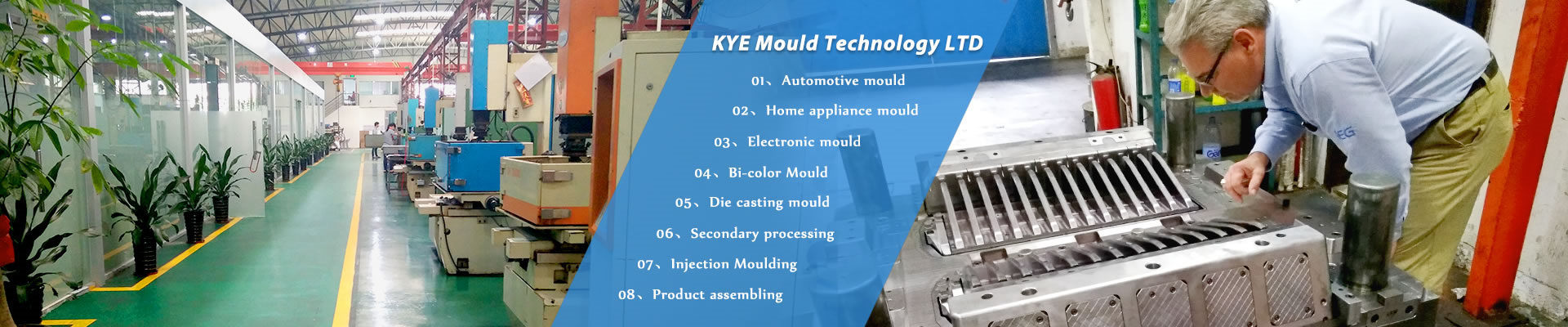

KYE Mould Technology Limited is a large scaled Chinese injection tool manufacturer with full experience on creating durable, high-quality molds and products. Our excellent engineered and experienced technical support to take your idea to be reality under one roof from mold design, prototype-making, Mold-flow analysis, molding to plastic part and die-casting parts producing.Industrial product accessories injection molding is one range of our main business.

These pipes serve as essential components in vacuum cleaners, allowing the user to extend the reach of the vacuum cleaner and access hard-to-reach areas. KYE is with the full experiece on vvacuum cleaner pipe injection mold and molding with precise dimensions and consistent quality.

Precision-engineered:KYE Vacuum cleaner pipe injection mold precision-engineered by KYE‘s expert team with state-of-the-art technology.KYE offer high-tech machining process (CNC, EDM or other techniques) to support the vacuum cleaner pipe‘s shape, size, wall thickness, and any other features necessary for the proper functioning be fine incorporated the mold design.

The vacuum cleaner pipes made by KYE mould is with high precision dimensions and smooth features. Our vacuum cleaner pipe injection molds are with first-level quality and meet DME/HASCO standard.

Prototyping: For ensure that the design adheres to safety guidelines for related product industry. KYE provide 3D printed prototype if neccessary.

Strict QC system: Quality Assurance is the key to success for KYE Moulds, high-quality/defect free products is the reason. Our quality control lab is equipped with optical Coordinate-Measuring achine(CMM), projector, Vickers/Rockwell hardness tester, salt spray tester,etc. Furthermore we have strict quality control process and related examination and testing stardards.

Trial running: While finish the mold assembly, KYE will arrange trial running and provide T1, T2 or T3 samples till meeting your satisfaction.

Trimming and Finishing: KYE experienced worker will trim off any excess material (flash) or imperfections after ejection, undergo additional finishing processes for vacuum cleaner pipes, so that it can achieve the desired surface texture and appearance.

Mass Production: Mass Production and Assembly also can be done under our one roof if our customers place product order to us directly.

Vacuum cleaner pipes are critical for the efficient operation of vacuum cleaners, and the precision and reliability of the injection mold are crucial in creating pipes that fit securely and function properly. These vacuum cleaner pipe injection molds providing by KYE are good aesthetics, durable, reliable and precision. KYE precision molding process ensures the vacuum cleaner pipe molds are manufactured with consistent quality (including dimensional accuracy and durability), and meeting industry standards and customer expectations.

|

1.Mould standard |

DME |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

S50C |

|

4.A/B plate steel |

P20 |

|

5.Core/Caviry steel |

H13 |

|

6.Runner type |

Cold runner |

|

7.Gate type |

Sub gate |

|

8.Cycle time |

40s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

4 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

0.5 million shots |