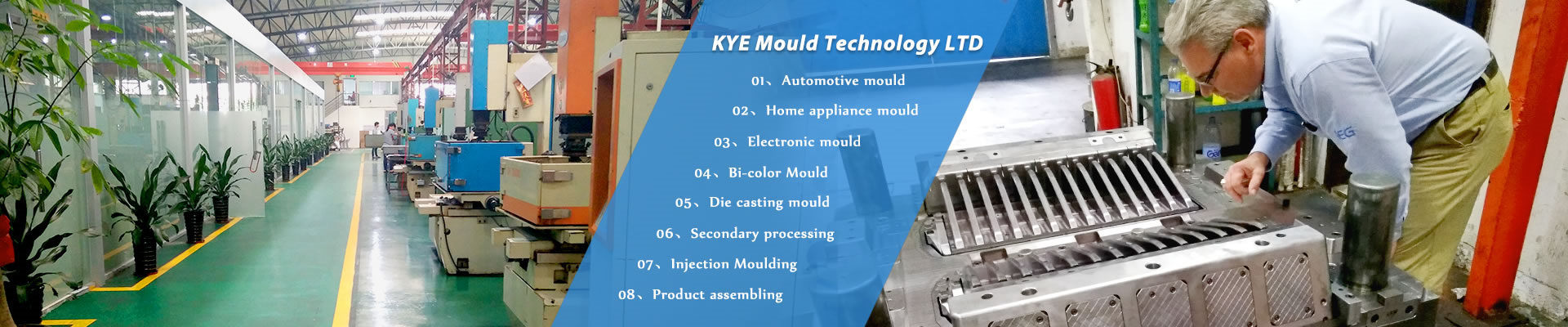

KYE Mould Technology Limited is a large scaled Chinese injection tool and die casting mould manufacturer with full experience on creating durable, high-quality molds and products. Our cutting-edge injection molding process and die casting techniques achived us stand out in a crowded market.

Precision-engineered:KYE die casting mold, KYE Fuel Filler Cap die-casting mould, precision-engineered by KYE‘s expert team with state-of-the-art technology.KYE expert team customized it with excelent process for the durable and precise Fuel Filler Cap.The necessary features for proper sealing, venting, and handling has been considered in our Alloy Die casting mould design.The Fuel Filler Cap Die Casting molds are with world-class quality and meet DME/HASCO standard.

Excellent Material Properties: The alloy material we choosed for press die-casting mould is with excellent heat conductivity, lightweight nature, and good mechanical properties.

Exquisited Process: Our superior die casting mold process to melting and ejecting appropriate metal alloy for the heat sink cover.Produce the metal parts rapidly with excellent dimensional accuracy and surface finish. The strength, durability, and consistency of the Alloy Fuel Filler Cap which die-casted by KYE mold can be guaranteed. Your products also will be ensured can withstand the test of time.

Strict QC system: KYE qc team will strict control the prouct quality, KYE experienced production lines will undergo surface treatments such as machining, polishing, powder coating, anodizing, or painting per the specific requirements and application, so that to improve its appearance and corrosion resistance

Trial running: While finish the mold assembly, KYE will arrange trial runner and provide T1, T2 or T3 samples till meeting your satisfaction.

Mass Production: Mass Production and assembly and also can be done under our one roof if our customers place product order to us directly.

Die casting is a cost-effective and efficient method for producing fuel filler caps that meet the strict quality and safety standards required for automotive and machinery applications. KYE press die-casting molds are with tight tolerances and consistent. The process is widely used in the electronics industry. KYE own our skilled mold designers, experienced die casting machine operators, and strict quality control measures throughout the manufacturing process. It‘s crucial for the reliable performance for achieving high-quality results.

|

1.Mould standard |

LKM |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

S50C |

|

4.A/B plate steel |

P20 |

|

5.Core/Caviry steel |

8407 |

|

6.Runner type |

Cold runner |

|

7.Gate type |

Edge gate |

|

8.Cycle time |

60s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

7 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

0.5 million shots |