KYE automotive component molds

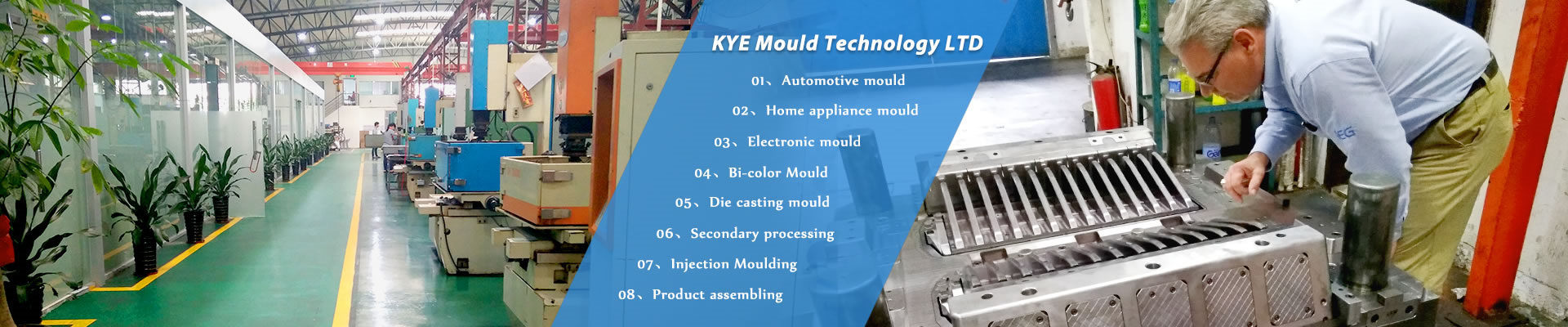

KYE is a professional exported mould manufacturer which with full experience on moulding for auto parts.

KYE automotive component molds are precision-engineered as per requirement and varying purpose by KYE’s expert team, all our molds are manufactured with the highest quality standards. We combine experience for 10+ years with state-of-the-art technology and innovative processes to deliver new levels of production capacity, performance, reliability, cost efficiency and overall customer satisfaction.

It‘s no problem even though the automotive components are varied, ranging from small interior parts to large exterior components. KYE have full experience on design and molding in the manufacturing process of automotive components parts.

All the automotive interior and outerior parts those we ever molded and manufactured, all have been attached with its unique character. Our commitment to innovation informs every aspect of our business. It’s a mindset and a strategy.

KYE automotive component molds strict control in the production of high-quality and standardized auto components for vehicles. We ensuring that the produced parts meet the required specifications in terms of shape, size, and functionality even though the complex designs. Work with KYE, the production process can be more efficient, resulting in cost-effective manufacturing and consistent quality across a large volume of automotive components.

|

1.Mould standard |

DME |

|

2.Mould type |

2 plate-mould |

|

3.Mould base steel |

S50C |

|

4.A/B plate steel |

P20 |

|

5.Core/Caviry steel |

H13 |

|

6.Runner type |

Hot runner |

|

7.Gate type |

Hot drop |

|

8.Cycle time5 |

50s |

|

9.Design software |

CAD, UG, Proe |

|

10.MOQ |

1 set |

|

11.Payment term |

T/T |

|

12.Package |

Artificial wooden box |

|

13.Deliverly date |

7 Weeks |

|

14.Mould number |

According to customer requirement |

|

15.Mould life |

1 million shots |